Industrial hoods and uptake systems

Bespoke industrial hoods tailored for energy saving and safe pollutants uptake

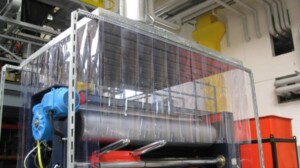

Hoods for industrial aspiration systems

Hoods make safe various operations typical of industrial processes: grinding, polishing and cleaning of components of various dimensions. Hoods may also be adapted to various working zones: mixers, agitators, sifters, reactors or other.

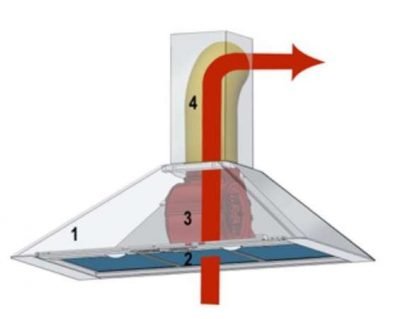

Hoods: How do they work?

Hoods suck air from typical operations of industrial processes. They are placed at the edges of working zones and are kept at low pressure by an appropriate centrifugal fan. Hoods are designed to capture dust or other pollutants directly where they are produced, safeguarding working zones and the health of the operators.

The aspiration system can be designed with one or more hoods, characterized by different flow rates and by manual or automatic operating cycles. Usually the aspired air is conveyed in a single pipeline, which directs the airflow to one or more filtering equipments that are designed on the basis of the specific pollutants to be treated (dust, solvents, oils,…).

Aspiration hoods: the importance of a proper design

Designing the right suction system is of utmost importance in order to obtain the highest removal efficiency and to optimize the amount of air aspired by the fans.

Tecnosida®, on the basis of the inspection of a specialized technician, can design hoods of various dimensions and geometry which are perfectly suited to your production process. The design of hoods is made taking into account:

- the peculiarities of your production process;

- available spaces;

- the characteristics of the specific pollutant;

- regulatory requirements;

- sizing and arrangement taking into account the ergonomic importance of the operator.

Fans: the importance of a proper choice

The choice of a proper fan is fundamental in order to guarantee an high efficiency and low energy consumptions. The main issues that Tecnosida® takes into account in the design phase are:

- the capture speed desired. This parameter depends on the type of pollutant to be treated and on the volumetric flow rate;

- the temperature of the airflow, that can be stable or variable;

- the design of the pipelines, that is made on the basis of:

- geometry of the industrial building;

- position of the filtering equipments;

- where hoods are placed in the production process.

On the basis of these data the pressure drops in the suction system can be determined. These data, in union with the desired volumetric flow rate, are used by Tecnosida® to dimension the most suitable centrifugal fan.

Hoods: maintenance service

Tecnosida® is a perfect partner for planning and execution of ordinary and extraordinary maintenance services required to :

- Verify hoods proper functioning

- Keep high filtration efficiency

- Reduce economic and energetic wastes

- Comply with safety and environmental rules and regulations

Contact us for more information