Dust separator multicyclones | TURBOVORTEX®

High-efficiency multi-cyclone dedusting technology

What is Turbovortex® multicyclone for dust removal?

Turbovortex® multicyclones represent the evolution of the traditional cyclone concept. Their flexibility and adaptability makes them ideal as pre-filters (when the dust content in the flow to be treated must be drastically reduced, to protect the main filter) or as stand-alone separators.

Turbovortex® multicyclones can be used in any sectors where high separation efficiency is required, without using mechanical filters. Our multicyclones are particularly used for treating emissions from wood chip, pellet and other solid biomass burning plants.

How does the Turbovortex® multicyclone work?

In dust separation systems using Turbovortex® components, the airflow to be treated is carried inside the body through a pallet system that gives it a vortical motion.

Dust and particulate within it, subjected to centrifugal force, separate from the vortex and move towards the internal walls reaching the lower exhaust opening. At this point, the purified gas flow inverts the direction and goes back into the inner tube to the exit.Turbovortex® is characterized by proprietary geometry and by an external structure that can be made in different shapes depending on the available space and customer needs.

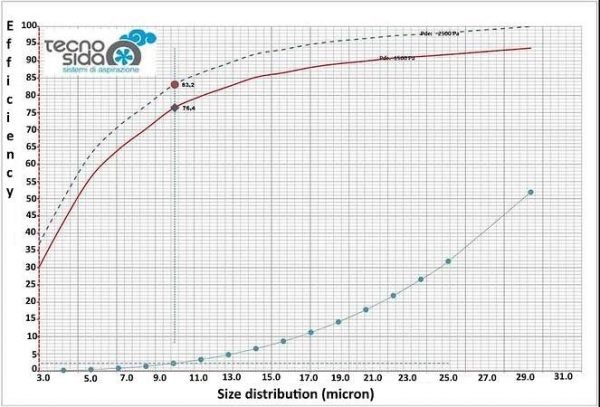

The multicyclone is made connecting in parallel the necessary number of Cyclone units in order to treat flows of any dimension and obtain very high separation efficiencies. As we have seen, Turbovortex® is based on the principle of centrifugal force so is efficiency strictly dependent on:

- granulometric distribution of the treated material

- physical-chemical characteristics

- flow speed

Due to the peculiarity of the operating system, is very important during the design phase to define the scope and the flow rate and the specific temperature of use. These two variables are very important for defining the working range and for creating the right balance between energy efficiency and pressure drop, thus ensuring maximum efficiency (as shown in the side chart). For this reason, Tecnosida® has equipped itself with a prototype used to test Turbovortex® efficiency in relation to several specific pollutants.

Tecnosida®, thanks to its long experience in the field (over 35 years), is able to design multicyclones with this perfect balance: contact us!

Strenghts of Turbovortex® multicyclone

The Turbovortex® technology:

- has very high separation efficiency;

- the product is very flexible and modular and can be adapted to flows that range from a few hundreds of cubic metres per hour to several tens of thousands (Tecnosida® offers solutions in carbon steel, stainless steel AISI 304 or special solutions for high temperature)

- it is equipped with varnish for high temperature (it is made of acrylic-silicone aluminum able to withstand temperatures up to 400°C);

- it can be made complete of external insulation, at various degrees of insulation, in order to avoid the undesirable effect of water vapor condensation possibly present in the emissions to be treated;

- REDUCED MAINTENANCE: It does not require any special maintenance and does not use consumables of any kind (cartridges, filters, etc..);

- ECONOMY: it requires a limited investment and has low running costs.

Contact us for more information: we will plan with you this important activity!

Turbovortex® multicyclone: maintenance service

Tecnosida® is a perfect partner for planning and execution of ordinary and extraordinary maintenance services required to :

- Verify multicyclone proper functioning

- Keep high filtration efficiency

- Reduce economic and energetic wastes

- Comply with safety and environmental rules and regulations

Contact us for more information