Bag filters for high temperature and combustion | DUSTdown® High Temperature

Reverse-jet de-dusting filters for high temperature and biomass combustion emissions

What is DUSTdown® High-Temperature bag filter?

DUSTdown® High Temperature is a very high efficiency self-cleaning mechanical filter, equipped with an automatic on-line cleaning system with a Reverse Jet of compressed air. It was designed by Tecnosida® to address the specific problems associated with treating emissions from solid biomass combustion (woodchips, wood, pellets, twigs, agricultural waste, rice husks, sunflower hulls and many others).

How does the DUSTdown® High Temperature bag filter work?

The air to be treated enters the lower part of the dust remover, passes through a pre-filtering chamber that allows the courser dust to precipitate, protecting the filter from excessive dust loads. The flow then reaches the filtering surface and passes through it with consequent realization of the separation of the particulate. The dust collected by the numerous sleeves precipitates to the bottom of the filter where the hoppers direct it to the collection system (cochlea, rotary star valve, clapet valve or screw with conduit/pipe) or automatic discharge.

The filtering surface is kept in perfect condition thanks to automatic cleaning cycles. These are managed on the basis of the filter pressure loss readings to limit the compressed air consumption and increase the lifetime of the sleeves.

Very important: Emissions from the solid biomass combustion are characterized by a high level of acidity which can lead to corrosion of the metal parts of the filter. For this reason, our DUSTdown® High Temperature is equipped with an automatic injection system of basic substances (lime, bicarbonate or other) that reduce the acid component of the fumes, preserving the internal structure of the filter and its functioning.

Strenghts of the DUSTdown® High Temperature bag filter

The DUSTdown® High Temperature filter:

- CUSTOMISATION: The Dustdown® filter is built and configured according to the customer’s specific use and dimensional needs in terms of flow volume, quantity/quality of the dusts, (grain size) and temperature;

- EFFICIENCY: The Dustdown® is designed to reach very high efficiency levels. More than 99.9% of the dust can be removed;

- ECONOMY: is considerably more economical in terms of purchase and maintenance costs, when compared with other dust removal technologies;

- Is designed with specific building materials in relation to the emissions to be treated. In addition, Tecnosida® adopts a special high-quality filtering surface, for continuous use up to a maximum flow temperatures of 250°C;

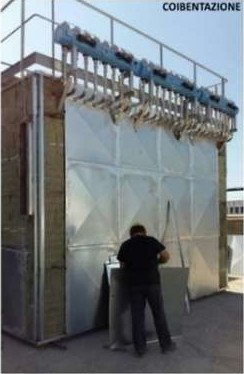

- Is designed with a standard insulation for the control of the condensation effect, caused by the high temperature range existing between the fumes saturated with water and the filter walls (at room temperature);

- Is simple, reliable and economic;

- May be designed for low or high volumetric flow rates, being constituted by modular panels;

Standard equipments of the DUSTdown® High Temperature bag filter

- Filtration chamber;

- Hopper with inspection hatches, collectors and support legss;

- Pneumatic cleaning system of the bags/cartridges, set by a differential pressure switch/economizer;

- Pre-separation chamber;

- Triboelectric sensor (mandatory for some applications);

- Specific insulation system.

DUSTdown® High Temperature bag filter: Available options

- Pressure regulator;

- Economiser;

- Anti-fire systems.

DUSTdown® High Temperature bag filter: maintenance service

Tecnosida® is a perfect partner for planning and execution of ordinary and extraordinary maintenance services required to :

- Verify filter’s proper functioning

- Keep high filtration efficiency

- Reduce economic and energetic wastes

- Comply with safety and environmental rules and regulations

Contact us for more information