Post combustore termico

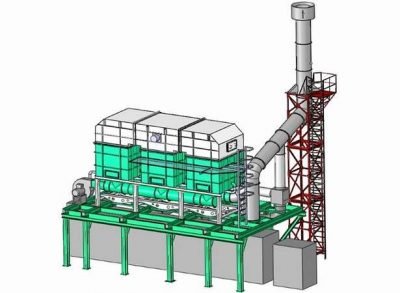

Ossidatore termico per la combustione di sostanze organiche

Cos’è un post combustore termico?

La post-combustione è un processo utilizzato, con ottimi risultati, per l’ossidazione termica di flussi d’aria contenenti inquinanti organici volatili sia alogenati che non.

L’ossidazione termica avviene all’interno di una camera di combustione dove gli inquinanti presenti nell’effluente da trattare vengono bruciati decomponendo generalmente l’inquinante in anidride carbonica (CO2) e vapore acqueo (H2O).

Post-combustione: tipologie e principi di funzionamento

Il processo termico, mediante ossidazione ad alta temperatura, si propone di trasformare i componenti nocivi in sostanze innocue: anidride carbonica (CO2) e vapore acqueo (H2O). Esistono diverse macchine per realizzare l’ossidazione termica: la scelta si basa su diversi aspetti come, ad esempio, la concentrazione degli inquinanti da trattare ed il livello di efficienza termica che si vuole ottenere. Di seguito analizziamo le macchine ossidanti esistenti.

Ossidatore termico a fiamma diretta:

Si tratta di un combustore termico senza recupero di calore. In pratica è una camera di combustione opportunamente studiata, dotata di bruciatore, che ossida termicamente gli inquinanti. Al termine della camera, a seconda delle esigenze del cliente, si possono inserire diverse tipologie di recupero (solitamente recupero su olio diatermico, acqua per la produzione di vapore o altro).

Ossidatore termico recuperativo:

Si tratta di un combustore dotato di recupero di calore. E’ costruito in modo tale che l’effluente entrante recuperi calore dai gas combusti, al fine di contenere il consumo di combustibile ausiliario. Inoltre, è possibile sfruttare ulteriormente il calore residuo nei fumi inserendo un secondo recupero di calore su aria o su acqua in base alle necessità.

Ossidatore termico rigenerativo:

Si tratta di un combustore il cui scambiatore per il recupero termico è di tipo rigenerativo. E’ costituito da materiale ceramico il quale, se opportunamente dimensionato, è in grado di raggiungere efficienze di recupero termico del 95% e oltre. Inoltre, in base alle concentrazioni di inquinanti ossidati, può potenzialmente condurre il sistema all’autosostentamento, azzerando quindi il consumo di combustibile ausiliario. Anche in questo caso è possibile ipotizzare un recupero finale del calore a camino su aria o su acqua.

Ossidatore termico catalitico:

Si tratta di un combustore che sfrutta un opportuno catalizzatore per far avvenire l’ossidazione a temperature più basse ( circa 300-400°C), mantenendo invariate le efficienze ambientali. Al sistema è possibile unire uno scambiatore di calore per aumentare il recupero termico, contenendo ulteriormente i consumi di combustibile ausiliario.

Nei processi che presentano composti alogenati si può formare acido alogenato relativo che, a valle dell’ossidazione termica, necessita di essere trattato tramite l’abbattitura ad umido dell’effluente, eseguita tramite il nostro scrubber wetclean.

Punti di forza del post combustore termico

Il post-combustore:

- garantisce il più alto rendimento di abbattimento, persino superiore a quanto richiesto dalle normative internazionali;

- viene proposto in unità modulari che consentono pre-assemblaggi rapidissimi, minimizzando così i tempi di montaggio in cantiere e il fermo macchine del cliente.

Optional aggiuntivi per il post combustore termico

Può essere progettato uno scambiatore di calore che permetta di recuperare ulteriormente il calore sensibile dei fumi uscenti. Tale calore sensibile può essere utilizzato per riscaldare aria, olio diatermico o acqua, oppure può essere utilizzato per produrre vapore.

Post combustore termico: manutenzione

Tecnosida® si occupa anche della programmazione di periodici interventi di manutenzione ordinaria e straordinaria per verificare la struttura dell’impianto. Tale servizio è disponibile anche per il post combustore termico e garantisce:

- corretto funzionamento del combustore;

- elevata efficienza di combustione;

- riduzione degli sprechi (sia in termini economici che energetici).

Per maggiori informazioni non esitate a contattarci: programmeremo con voi questa importante attività!

Post combustore termico: telegestione

Il postcombustore termico può essere dotato di sistemi di telegestione per il monitoraggio delle prestazioni e del funzionamento.

Contatta Tecnosida per ricevere una consulenza specifica ed aderente alla situazione tecnica della tua azienda!